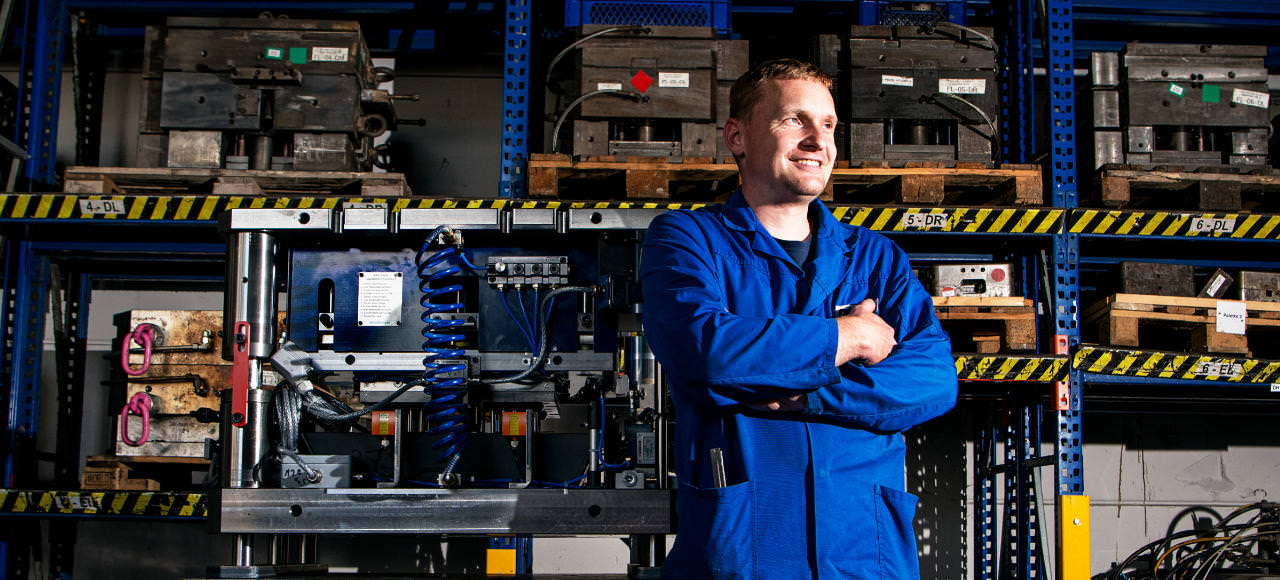

We are your enablers

From technically optimised development to forward-looking production and reliable just-in-time delivery, everything comes from a single source. As a result of our experience in metallurgy and in the field of special alloys, we accompany your product through all stages of development.

Contact usProduct development is teamwork

Together with your engineers, we develop the basis for a high-quality and cost-efficient series production. In this process, the design and the material play a leading role.

More about product developmentManufacturing including fine tuning

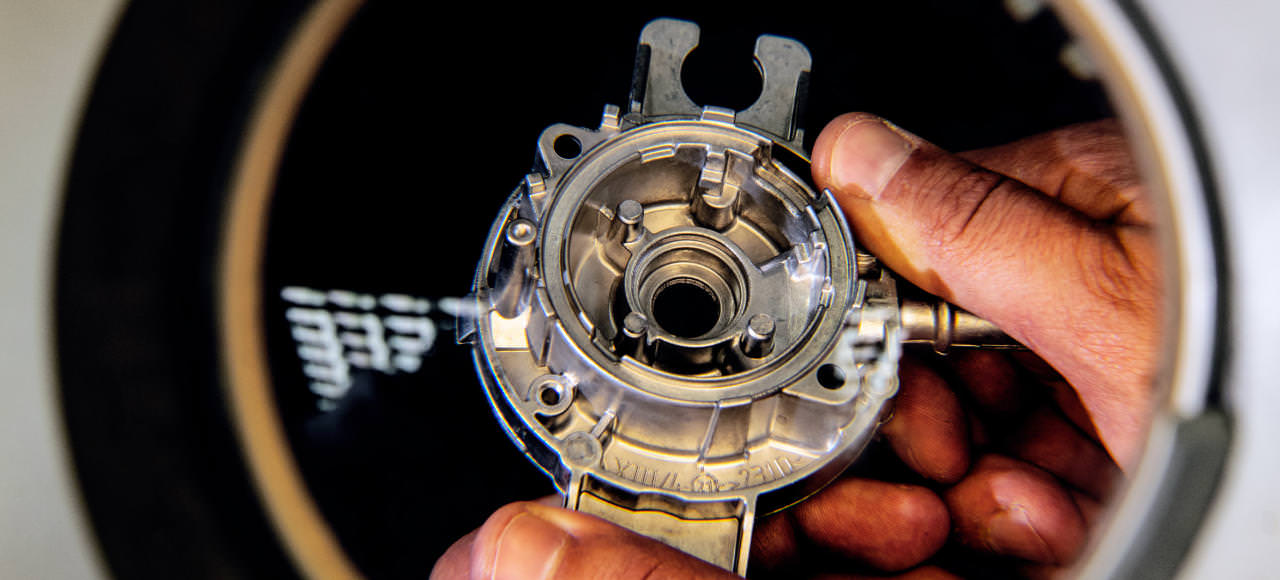

Once the requirements for the product have been finalised, it goes into production and is manufactured using one of our two casting processes - Die Casting or Thixomolding. It then goes through CNC machining, cleaning and surface finishing for the final touches.

More about manufacturingAluminum and magnesium are waiting to be applied

Whether you choose aluminum as an extremely strong lightweight metal or magnesium as a strong super lightweight metal, we offer optimum solutions for your requirements with different alloys.

More about materialsInspected and tested

Every production step is monitored by our quality management team so to ensure that all product requirements are met. Starting from the quality check of the raw material to the final inspection of the end product.

More about quality management